Mechanical maintenance

- Full inspection of the equipment, verifying factory settings

- Verify air-tightness and check that there are no leaks, drag, or pipes affecting equipment efficiency.

- Inspection of water distribution system and proper functioning of its jets

- Verify that the hydraulic inlet, outlet, drain, overflow and water replenishment connections are correct

- Inspect the quality of recirculation water according to the recommended parameters, and present alternative solutions for your system

- Inspection of torque and bolts in mechanical equipment, alignment and factory settings for the motor system

- Inspection of ventilation systems according to specified torques, alignment, angles and design settings

- Check vibration in motor systems comparing against your ISO10816 standard

- Cleaning of cold and hot water basins, as well as their transfer areas

- Inspection of oil levels in gearboxes, verification of operating conditions and protection recommendation

- Installation of Silver Bullet® equipment defined by the volume to be treated in the tower

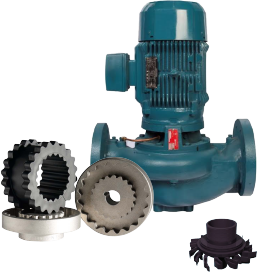

Spare Parts

We offer you a

wide range of

spare parts for IM

towers and other

brands.

Major repairs

It has IM to throw your tower back. We make repairs From spare parts to mechanical service. get in touch With one of our experts.

Request your service